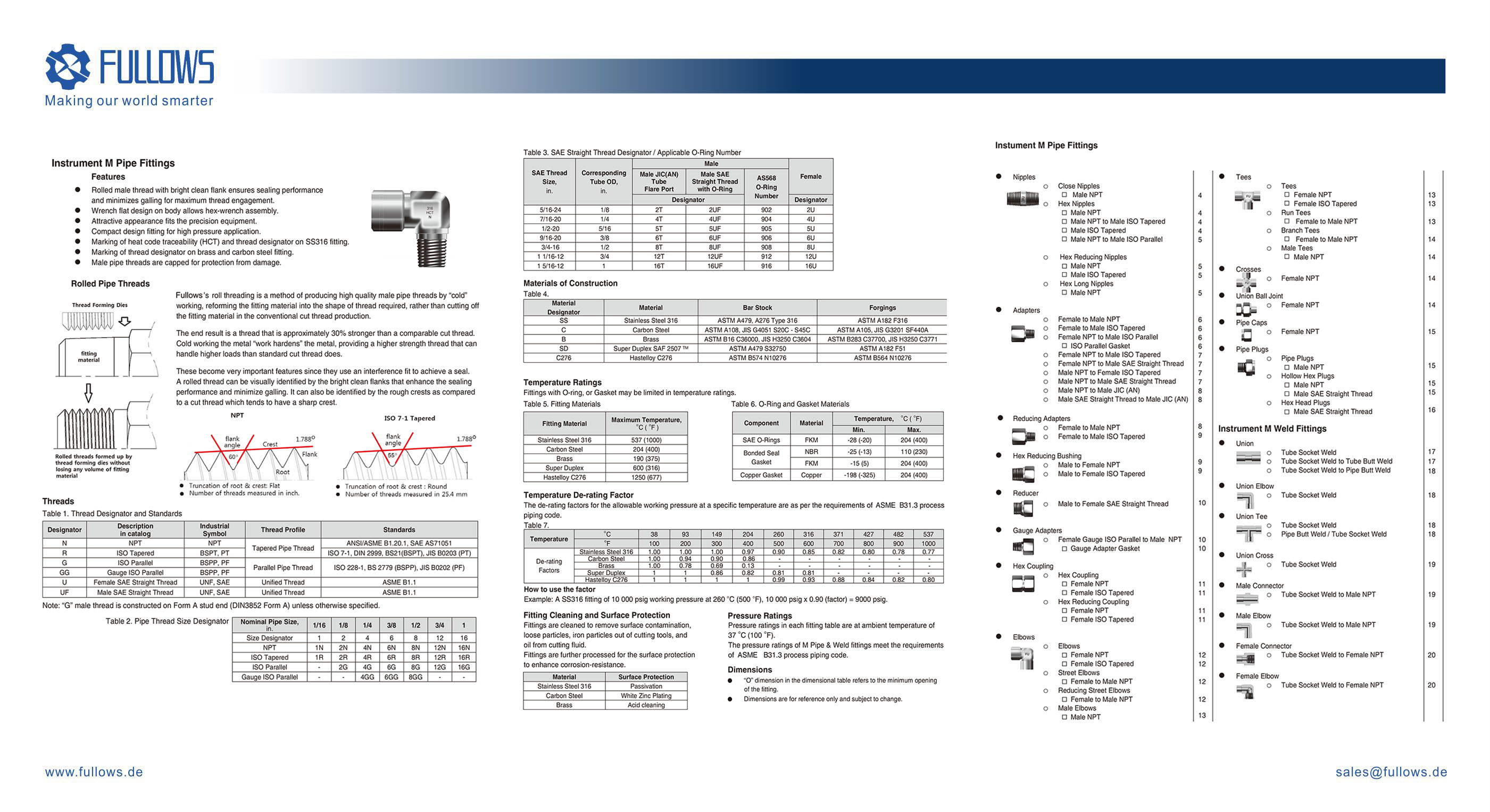

Fullows Instrument M pipe & Weld fittings

Features

- Rolled male thread with bright clean flank ensures sealing performance

- Wrench flat design on body allows hex-wrench assembly

- Attractive appearance fits the precision equipment

- Compact design fitting for high pressure application

- Marking of heat code traceablity (HCT) and thread designator on SS316 fitting

- Marking of thread designator on brass and carbon steel fitting

- Male pipe threads are capped for protection from damage

Fullows roll threading is a method of producing high quality male pipe threads by "cold" working, reforming the fitting material into the shape of thread required, rather than cutting off the fitting material in the conventional cut thread production.

The end result is a thread that is approximately 30% stronger than a comparable cut thread. Cold working the metal "work hardens" the metal, providing a higher strength thread that can handle higher loads than standard cut thread does.

These become very important features since they use an interference fit to achieve a seal. A rolled thread can be visually identified by the bright clean flanks that enhance the sealing performance and minimize galling. It can also be identified by the rough crests as compared to a cut thread which tends to have a sharp crest.