Double Offset Butterfly Valves

Fullows Double Offset Butterfly Valves

Introduction of Fullows Double Offset Butterfly Valves

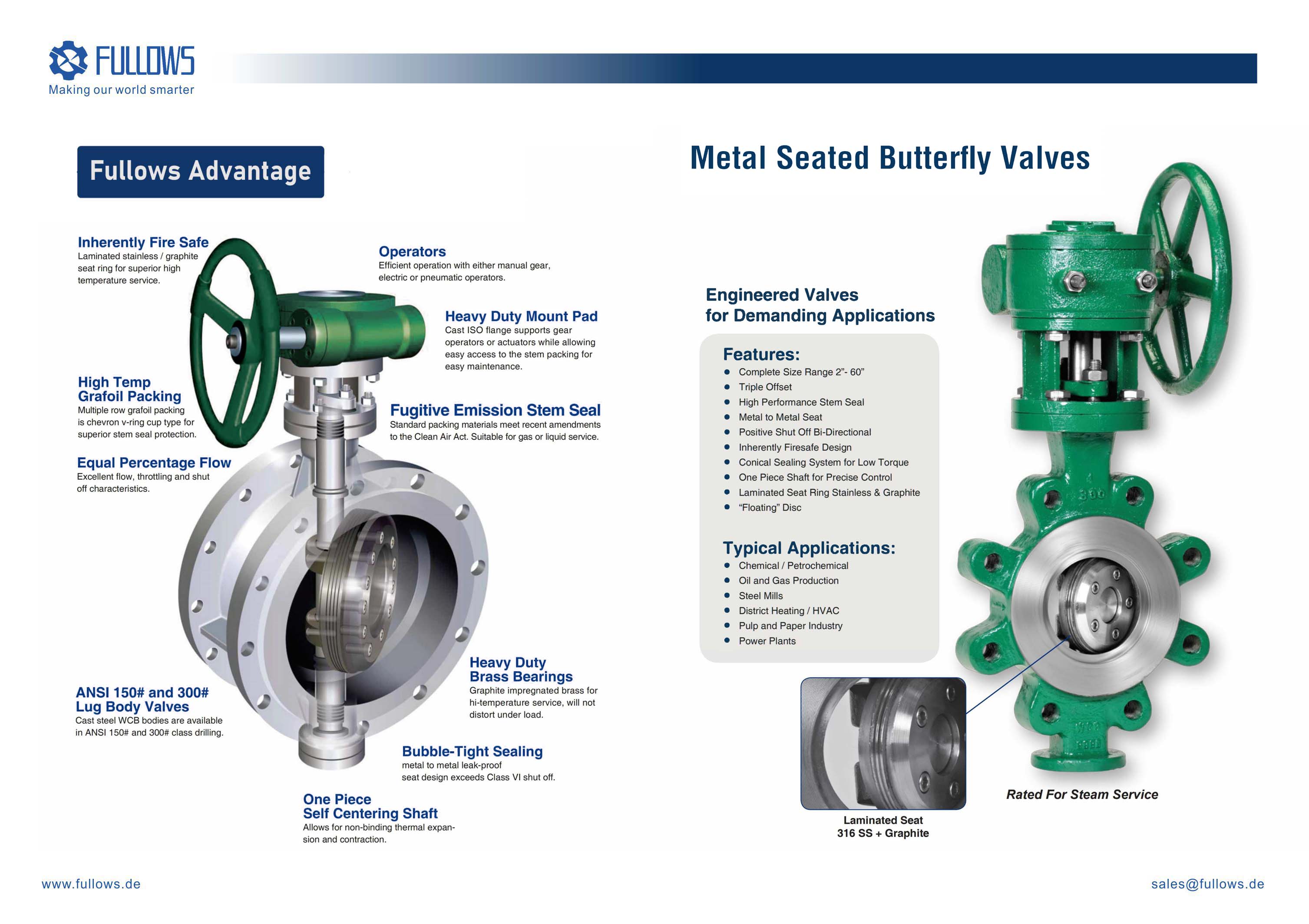

Fullows - ProCentric double offset

The first offset is between the center of stem and the center of the seat. This offset puts the stem behind the sealing surface for gradual disc engagement when the disc moves in and out of the seat. This Fullows action prevents cutting or pinching of the seat.

The second offset is between the center of the valve and the center of the stem. This offset allows the disc to swing free of the seat in the open position. This fullows action reduces seat wear, and minimizes seating torque, to create an eccentric seating action for high cycle applications.

Fullows - High performance stem seal

The precision machined packing chamber allows a maximum amount of PTFE Chevron packing rings. The narrow chamber keeps the v-ring packing stacked closely and securely to the valve shaft during high cycle applications.

The superior finish of the interior packing chamber and valve shaft assures long service life. The smooth finish reduces friction and maintains a zero leak, zero emission stem seal.

Constant 360° “even packing load” is exerted on the packing through the adjustable two piece packing gland. Studs connected to the valve body distributed the load evenly for ZERO stem leakage.

Fullows - Energized RTFE seat design

Pressure assisted PTFE seats are reinforced with 15% glass and achieve bi-directional bubble tight close off. The unique sealing system includes a Viton encapsulated core that energizes the RTFE and provides memory.

- Under higher pressure conditions the energized seat is engineered to direct the seat energy against the disc edge

- Disc and system pressure energized the seal as pressure is increased. High pressure leads to tighter shutoff and superior sealing

- The energized Viton core seat is isolated and protected from media contact by the Teflon encapsulation

Fullows - Fire safe seat - API 607 Tested

The RTFE + Inconel back up ring is engineered to seal off pipeline flow in the event of a fire. In normal operation the RTFE seat with Inconel metal back up ring allows bi-directional bubble tigh close off up the full ANSI rating.

In emergency fire conditions, the line pressure is immediately reduced and the area is foamed to extinguish the fire. The resulting pressure loss and rapid cooling causes many valves to fail. Because the Fullows seat design does not rely on media pressure to seal, the back up ring performs in fire safe conditions to safely contain the flow.